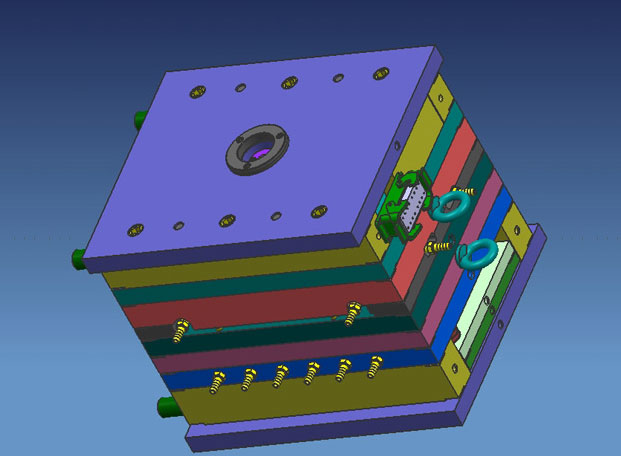

Our design team is capable of designing of moulds with innovative thinking and simple solutions, this enables the manufacturing of moulds in a very effective manner. We conduct process like Design feasibility modeling (DFM), Design for manufacturing and assembly (DFMA) during interaction with customers for the better output of the product.We also induce fool proof mechanisms and safety measures in our design to prevent it from any mishandling in future. We are deliberate on productivity of mould by increasing its life time.

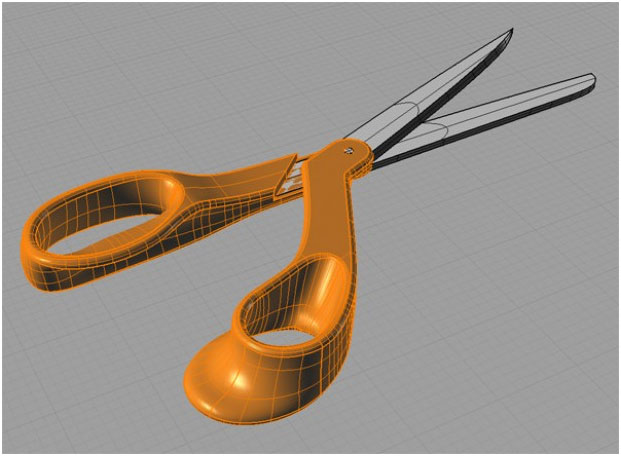

Conceptual design is the starting point of any product development process, through sketches, 3D renderings and other techniques.we develop multiple concept ideas based on the product requirement.It's always our endeavourto provide as many ideas as possible in the available time frame. Our team of experts having experience in automotive, electronics and consumer appliances will help you to save product cost by effective design.

We have a very good tooling capability with a promising infrastructure and facilities to machine the moulds in a high range of precision as expected by the customers. We go through a systematic approach followed by conducting design reviews and maintaining the records of the action plans in order to achieve zero failure delivery commitments. We also undertake mould maintenance work and try to improve the functioning of the mould by bring down the breakdowns by troubleshooting at our best.

Reverse engineering creates 3D design CAD models directly from physical parts. Through the reverse engineering process, we extract the digital shape of physical objects that may have insufficient design documentation or that require CAD data for modern manufacturing methods. The scanning process allows a component to be quickly and accurately reverse engineered.

The 3-dimensional data that is collected and modeled, can be used to troubleshoot, reproduce, study, analyze, inspect or can be applied to other future applications i.e. product enhancements. 3D CAD models can be easily updated for changes in the product design and mould design.